Kyoung-Yong Chun, Shi Hyeong Kim, Min Kyoon Shin, Cheong Hoon Kwon, Jihwang Park, Youn Tae Kim, Geoffrey M. Spinks, Márcio D. Lima, Carter S. Haines, Ray H. Baughman & Seon Jeong Kim

Kyoung-Yong Chun, Shi Hyeong Kim, Min Kyoon Shin, Cheong Hoon Kwon, Jihwang Park, Youn Tae Kim, Geoffrey M. Spinks, Márcio D. Lima, Carter S. Haines, Ray H. Baughman & Seon Jeong Kim

Center for Bio-Artificial Muscle and Department of Biomedical Engineering, Hanyang University, Seoul 133–791, South Korea

Kyoung-Yong Chun, Shi Hyeong Kim, Min Kyoon Shin, Cheong Hoon Kwon, Jihwang Park & Seon Jeong Kim

IT Fusion Technology Research Center and Department of IT Fusion Technology, Chosun University, Gwangju 501–759, South Korea

Youn Tae Kim

ARC Centre of Excellence for Electromaterials Science, Intelligent Polymer Research Institute, University of Wollongong, Wollongong, NSW 2522, Australia

Geoffrey M. Spinks

The Alan G. MacDiarmid NanoTech Institute, University of Texas at Dallas, Richardson, Texas 75083, USA

Márcio D. Lima, Carter S. Haines & Ray H. Baughman

*Corresponding author.E-mail: sjk@hanyang.ac.kr.

원문 링크 : http://www.nature.com/ncomms/2014/140221/ncomms4322/abs/ncomms4322.html

Abstract

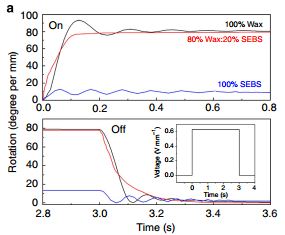

Torsional artificial muscles generating fast, large-angle rotation have been recently demonstrated, which exploit the helical configuration of twist-spun carbon nanotube yarns. These wax-infiltrated, electrothermally powered artificial muscles are torsionally underdamped, thereby experiencing dynamic oscillations that complicate positional control. Here, using the strategy spiders deploy to eliminate uncontrolled spinning at the end of dragline silk, we have developed ultrafast hybrid carbon nanotube yarn muscles that generated a 9,800 r.p.m. rotation without noticeable oscillation. A high-loss viscoelastic material, comprising paraffin wax and polystyrene-poly(ethylene–butylene)-polystyrene copolymer, was used as yarn guest to give an overdamped dynamic response. Using more than 10-fold decrease in mechanical stabilization time, compared with previous nanotube yarn torsional muscles, dynamic mirror positioning that is both fast and accurate is demonstrated. Scalability to provide constant volumetric torsional work capacity is demonstrated over a 10-fold change in yarn cross-sectional area, which is important for upscaled applications.